Exploring The Sun With Calmont Cables

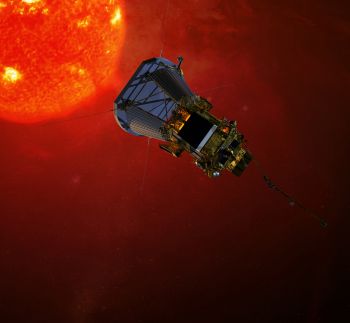

A year from now Calmont Wire & Cable will head for the the Sun. On July 31, 2018, NASA’s Parker Solar Probe will enter it’s launch window and begin a historic mission to explore the Sun. Many of it’s systems will be powered with wire and cable designed by Calmont. High Temperature Wire According to …

Custom cables for medical devices

Custom wire and cable is often the choice for medical devices due to the complexity of the technology of new devices. Custom medical wires and cables differ from applications in other industries because the medical devices are not only expected to perform but in many cases to withstand sterilization and be bio-compatible as well. When …

3 Reasons People Choose Custom Wire

Wire is wire right? Why would anyone need custom wire? Wire is constructed differently, it is important to use a wire that was made for your type of application. There are many reasons people turn to custom wire. Custom wire can be manufactured to meet specific requirements such as, high voltage, extreme temperatures, high …

Custom Ultra Flexible Hook Up Wire by Calmont

For over 50 years Calmont has been manufacturing custom wire and cable and we are known for manufacturing custom ultra flexible hook up wire. Calmont’s proprietary lines of custom ultra flexible hook up wires are a perfect fit for applications with demanding flex requirements. When you need ultra flexible wire from 40AWG to 4/0, we …

continue reading “Custom Ultra Flexible Hook Up Wire by Calmont”

Custom Wire and Cable: Tips for getting the right cable

When do you turn to a custom wire or cable? Custom wire and cable is needed more often than not. There are a variety of reasons design engineers turn to custom wire and cable for their projects, but the main reason is simply they cannot find a ready-made cable that meets all their requirements. Making …

continue reading “Custom Wire and Cable: Tips for getting the right cable”

Medical Cables: Preventing Redesign

It is common to make changes to medical cables for medical devices from the original design. The reasons medical cables often are redesigned is to improve performance, add flexibility to a cable or eliminate cable design flaws. Often, minor design changes are made to the medical cable as feedback from the end user and/or field …

Custom Configurations for Medical Cables

Every medical cable application is different so why settle for an off the shelf solution for a unique problem? I read quite a few discussion boards and find that when someone is looking for a specialized medical cable that the replies usually tell them to call Belden or Alpha. There is nothing wrong with Alpha …

Medical Cables vs. Generic Cables: Is there a difference?

Medical cables do differ from generic cables used in other industries. It isn’t recommended to use standard/ generic wire and cable in your medical device design unless the wire or cable doesn’t need to meet any medical requirements or is used internally in your device. Every industry has it’s unique requirements when it comes to …

continue reading “Medical Cables vs. Generic Cables: Is there a difference?”

Extruded shapes: Flat Cables to Wine Corks

Custom wire and cable manufacturers have the ability to extrude a variety of shapes, from round, flat cables, odd shaped cables, tubing to wine corks. Extruding machines can be outfitted with dies and tooling to create different extruded shapes. The extrusion process is different than injection molding, the heated plastic or rubber material is forced …

continue reading “Extruded shapes: Flat Cables to Wine Corks”

High voltage cables can be super flexible

High voltage wire applications can be found in every industry. High voltage wire and cable doesn’t have to be bulky and stiff. High voltage lead wire and cables can be manufactured to be extremely flexible wire and cable while meeting high voltage requirements by using high strand conductors and flexible wire insulation and jacket materials. …

continue reading “High voltage cables can be super flexible”