Calmont Introduces Med FlexWire for Disposable Medical Devices

Med FlexWire & Cable Our flexible lead wire has a soft, smooth biocompatible PVC jacket that meets USP class VI standards. It is made of specially compounded and plasticized polyvinyl chloride insulation applied over ultra-fine stranded wire that yields a finished wire with a longer flex life and a higher flexure index level than that …

continue reading “Calmont Introduces Med FlexWire for Disposable Medical Devices”

Calmont Wire & Cable Recieves ISO 13485 Certification

Calmont Wire & Cable has been registered by NSF-ISR the ISO 13485:2016 certification for its Santa Ana, California, manufacturing facility. The certification is for the design and manufacturing of customer wire and cable for medical device applications. ISO 13485 is the leading quality management standard for manufacturers of medical devices. “This ISO certification demonstrates Calmont’s …

continue reading “Calmont Wire & Cable Recieves ISO 13485 Certification”

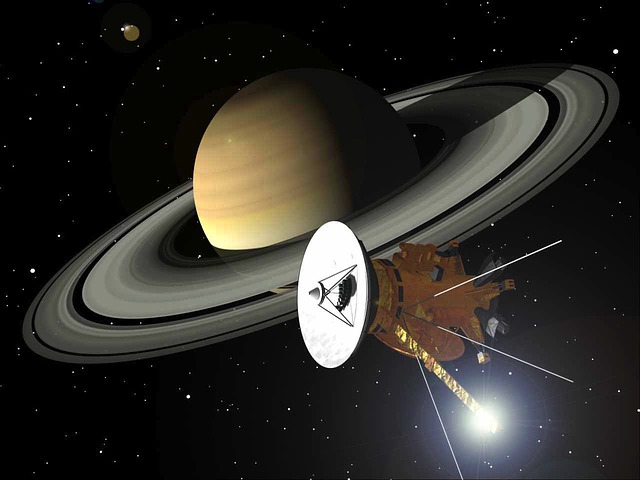

Cassini – Mission Accomplished

The Cassini-Huygens spacecraft was launched in October 1997 to study the famous rings and moons around Saturn. The spacecraft finally reached Saturn and began orbiting the planet nearly seven years later and, today, after 13 years in orbit and 20 years in space, Cassini plunged into Saturn’s atmosphere marking the end of one of the …

Silicone Wire – Art With Custom Wire And Cable

Custom wire and cable in art? One usually doesn’t think of custom cable and art in the same thought. But from time to time Calmont is contacted by artists looking for custom wire and cable for their art projects which are usually in the way of sculptures. Often times the custom wire is part of …

continue reading “Silicone Wire – Art With Custom Wire And Cable”

The Most Popular Applications for Silicone Wire and Cable

Silicone insulated wire and cables are a popular choice for a variety of industries due to it’s operating temperature range, extreme flexibility, voltage properties. Silicone wire and cable compounds are available in special grades and formulas are available for specific requirements such as, medical grade/implantable, low smoke/halogen-free, increased resistance to abrasion , flame retardant and …

continue reading “The Most Popular Applications for Silicone Wire and Cable”

Robotic Wire and Cable Selection Tips

It would be nice to go online and simply purchase robotic wire or cable for your robotic application. The truth is, selecting the right wire for robotics isn’t that easy. Robotic movements vary and have different levels of demand on the robotic wire. Movement includes repetitive flexing, torsion/twisting and bending at multiple points. Off the …

Super Flexible High Voltage Cables

High voltage wire applications can be found in every industry. High voltage wire and cable doesn’t have to be bulky and stiff. High voltage lead wire and cables can be manufactured to be extremely flexible wire and cable while meeting high voltage requirements by using high strand conductors and flexible wire insulation and jacket materials. …

Disposable vs. Reusable Medical Cables

Medical Hand Piece Cables Cables for medical hand pieces must carry the power, control, sensor and data to and from the hand piece. The cable may be as simple as a two-conductor cable, providing power to a cut & cauterize scalpel or a multi-conductor power, control and sensor cable used on an orthopedic surgery device. …

Medical Grade Silicone Applications

Silicone insulated wire and cable is an excellent choice for medical cable applications. Besides being extremely flexible, silicone rubbercan withstand autoclave and other forms of sterilization. Properties that make silicone suitable for medical applications include: Low thermal conductivity, low chemical reactivity, low toxicity and thermal stability (consistency of properties over a wide temperature range of 100°C …

Medical Cables and Sterilization

Medical cables are manufactured using a variety of materials. Reusable medical cables often times are subjected to sterilization processes and are built to endure extended cycles of sterilization. Understanding how a wire or cable will be sterilized is crucial to determine what materials to specify when designing a medical device. Insulation and jacket materials vary …